Design philosophy of the NG-2 GOBLIN

The NG-2 GOBLIN was designed in 2019 and basically follows the design philosophy of the original NG-1. But, as always, you learn. So the NG-2 was an effort to reduce the overall complexity of a blaster while optimizing it for easy printing and quick assembly. After all, 3Dprinting is rather scalable by simply investing in new machines. However, post processing, assembly, testing and shipping quickly become bottlenecks in production.

Minimal size was one of the early design drivers. So compared to the NG-1, which has massive 380 motor,, the GOBLIN features 180s. Simplicity was another driver. The choice to keep brushless motors was also a conscious one. Those run directly on DC from any battery. Weight specific power density is somewhat lower compared to brushless motor, but the effect is barely noticeable in this specific application. In contrast, no EMC is required. And, DC motors are readily available in bulk due to the fact that they are used in countless household items. The GOBLIN feature genuine high current switches and large gauge silicon wires.

Instead of full length darts, half length darts were chosen using Talon mags (Katanas proved to be quite unreliable) . The GOBLIN reaches between 120-130 fps max.

In order to cope with potential heat generated by the motors, the entire motor cage of the NG-2 is printed in ABS. This expands the temperature envelope to roughly 100°C.

If the battery is empty, no tools are required to remove it. A large lid grants direct access to the battery compartment. We use a 2s lipo measuring 58x30x15 mm. Both the 'Graphene 2s 950mAh 65c' from Outofdarts and the 'Turnigy Graphene Panther 1000mAh 2s 75c' from Hobbyking also fit. The GOBLIN is equipped with an XT-60 connector.

Another advantage of 3D printing is the fact that it allows us to use a lot of different colors and combine them in many different ways. For that purpose we prepared a color picker here.

The overall design has been kept highly modular. A dual cage version (DC) of the GOBLIN boosts fps to about 150. This is accomplished with a slightly longer nose that houses 4 motors.

Lately we added some accessories to the NG-2. Among those is an adjustable stock and fore grip.

The GOBLIN is available from our online store

or ETSY.

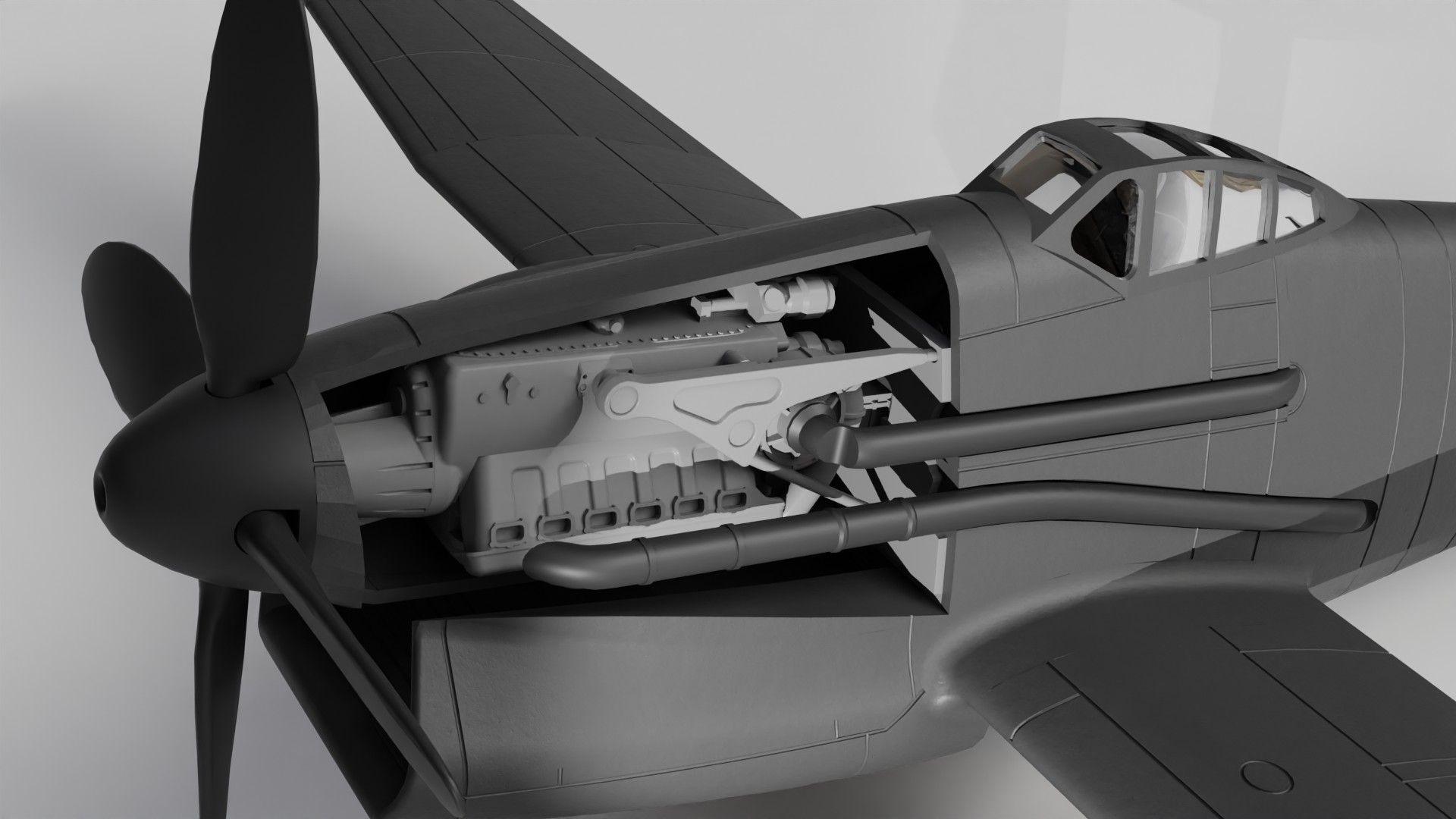

Bringing the Heinkel P.1068 to Life For aviation history enthusiasts and model builders, the Heinkel P.1068 is one of the lesser-known yet highly intriguing Luft ’46 aircraft concepts. Originally developed as a twin-engine competitor to the Arado Ar 234 , it evolved into a more advanced bomber featuring up to six engines. Though the He 343 project was ultimately canceled, the P.1068 survived in a different form—as a test aircraft built in collaboration with DFS (Deutsche Forschungsanstalt für Segelflug) . Now, you can bring this advanced jet bomber concept to life with our latest Heinkel P.1068-01 model kit , available exclusively at My3DBase .

Damit Eure Kekse mit unseren Backförmchen so richtig gut funktionieren haben wir für euch ein paar Tips zusammengestellt. Vorab einmal das Rezept: 100 g Butter 50 g Puderzucker (kann dem eigenen Geschmack angepasst werden) 30 g Ei 200 g Mehl Die Mengen können unter Einhaltung des Mischungsverhältnisses erhöht werden. Zunächst wird der Puderzucker mit der Butter vermengt. Danach wir das Ei hinzugegeben. Anschließend wird das Mehl untergehoben. Wichtig: Damit der Teig die richtige Konsistenz erhält sollte er gekühlt werden; ca 30min im Gefrierfach oder 1-2 Stunden im Kühlschrank.