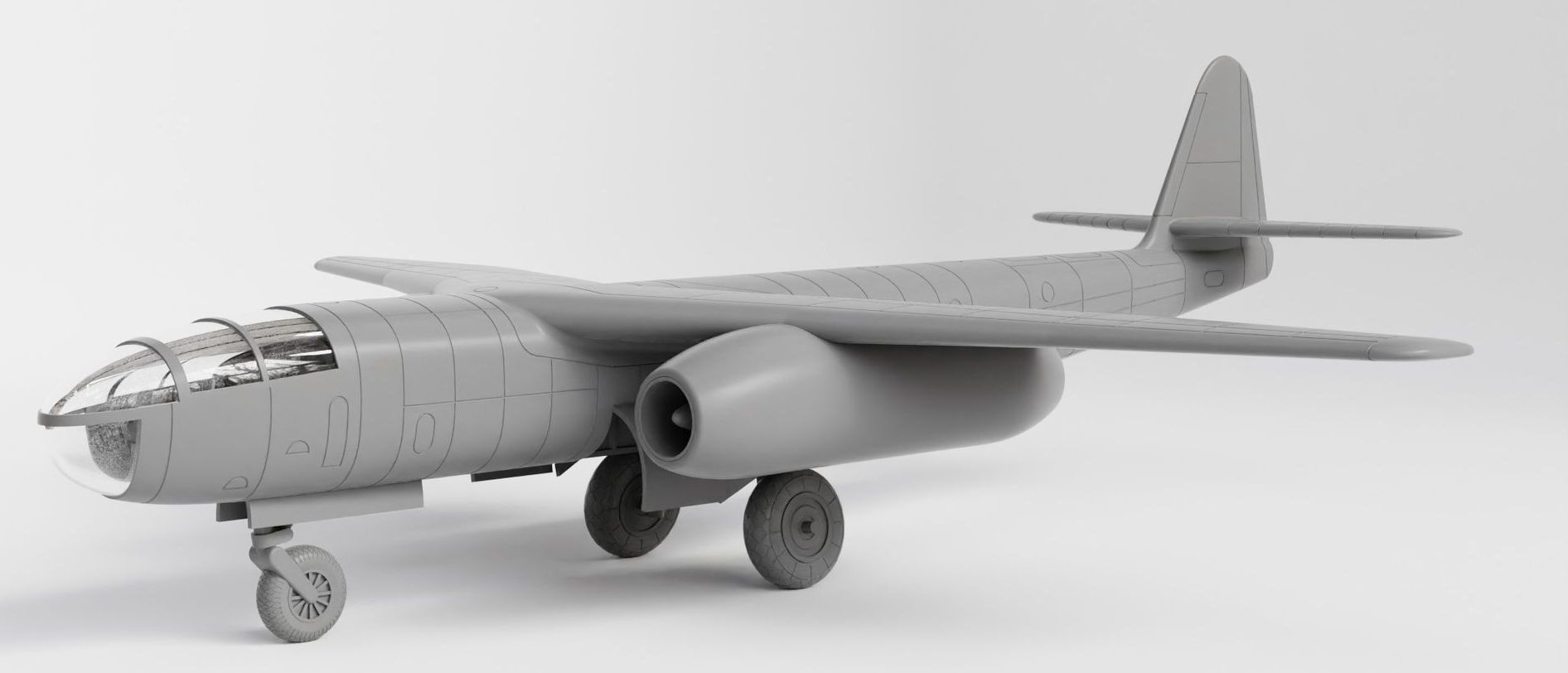

ARADO E.395 model kit development

Outline

Similar in apearence to the Arado 234, the E.395 was a design proposal by Arado for the Strahlbomber competition [Hitler's 'Wonder Weapon' Bomber Projects Luftwaffe Secret Bombers of The Third Reich, by Dan Sharp]. As such, it was both longer and had a greater wing span.

Two different and interchangeable wing design were proposed, a straight wing and a crescent version.

The design proposal outlines two different engine configurations; with HeS 011 or Jumo 012. Drawings seem to depict a four engine configuration with HeS 011's with a total thrust of approximately 50kN. That value would be reached or exceeded with only two Jumo 012's. Leading to the conclusion that only two Jumo's were planned, despite the lack of information in primary sources to confirm that assumption. Only one drawing shows the Jumo version. But that sideview does not visualize the number of engines.

General Data

Overall aircraft data is shown in the table below.

Weight Data

Overall aircraft weight data is shown in the table below.

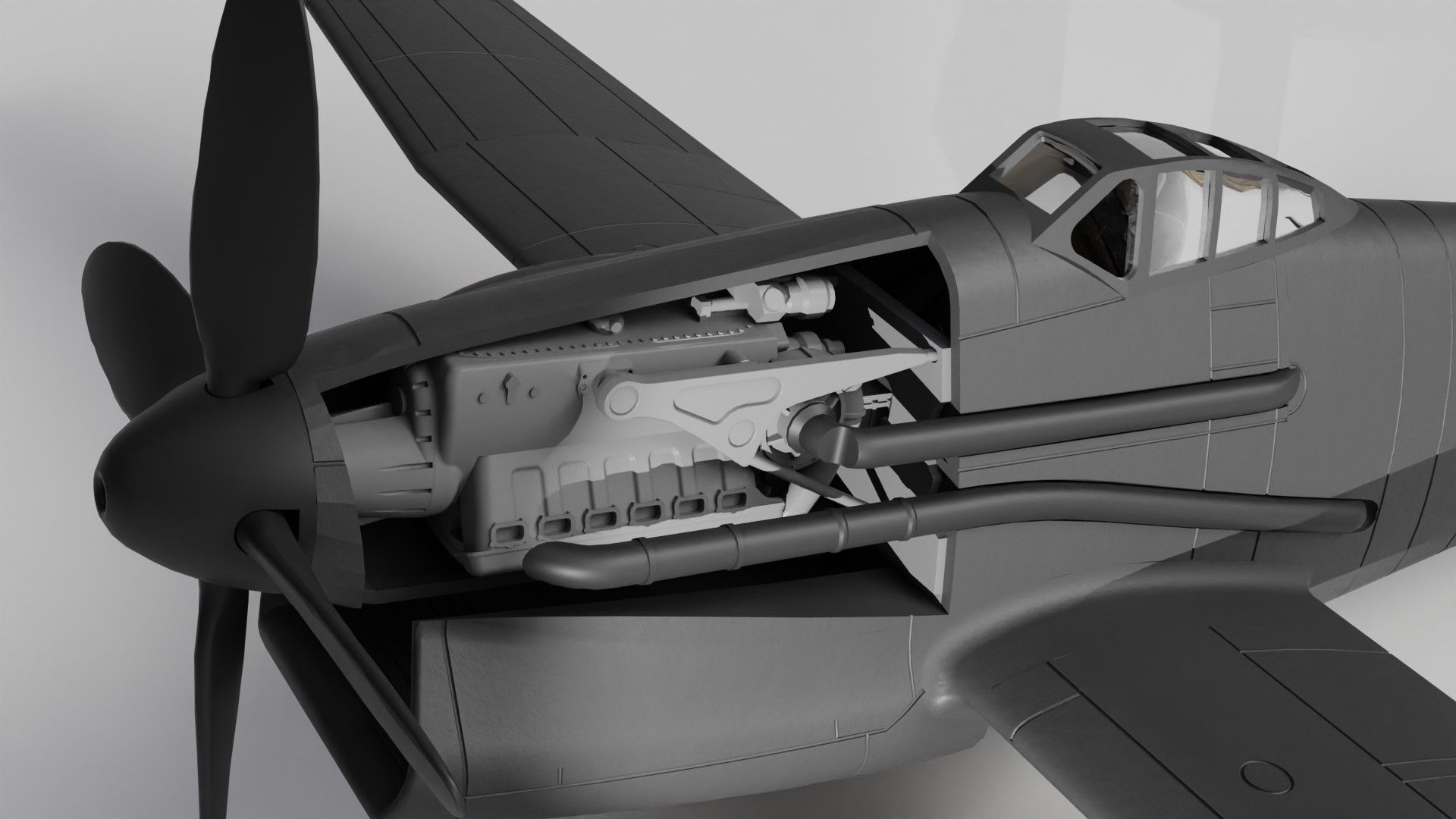

Engines

Only little information is available on the Jumo 012 engines. This Jumo engine configuration is the most interesting one however. There are only a handful of aircraft designs planned to use this engine which was in it's initial planning phase. Development of the engine was continued after WW2 in Russia.

Jumo 012A dimensions (Source http://hugojunkers.bplaced.net/junkers-jumo-012.html ):

More information about the Jumo 012 in Russia can be found in old CIA reports: https://www.cia.gov/readingroom/search/site/Jumo%20012%20Development%20at%20Kuybyshev

General layout

Overall layout of the design is assumed to be similar to the 234. A good source of information is the 234 handbook.

Images of frame 4 and 15 are displayed below (Source: 8-234 B-2 Flugzeug Handbuch). Frame 4 also serves as the back wall of the cockpit and contains a fitting for the nose landing gear.

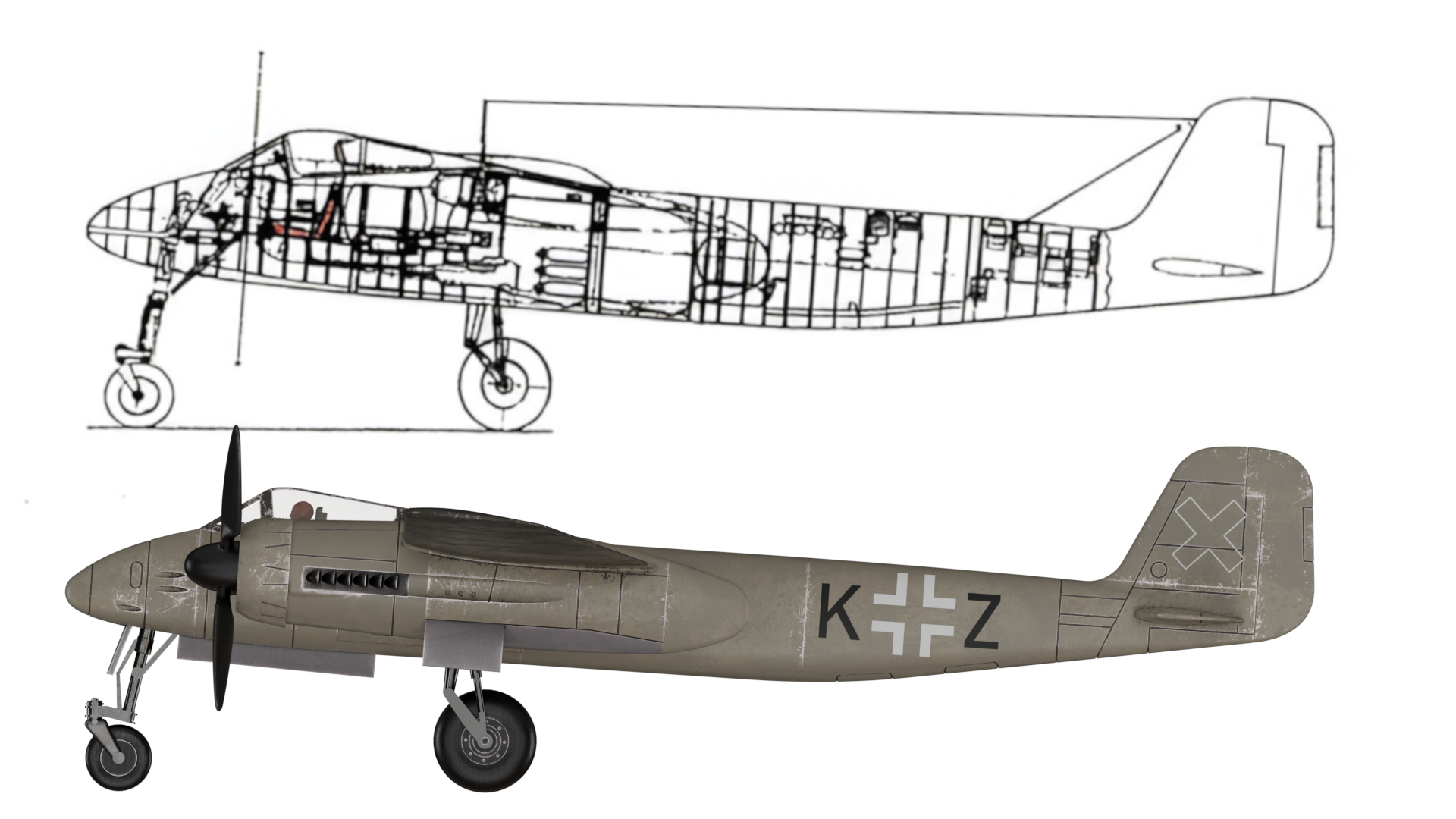

The image below shows an original drawing of the E.395 (slightly enhanced/ Jumo version).

Landing Gear

Due to it's similarities with the 234, it can be assumed that many other design characteristics can be directly applied to the E-395.

The nose landing gear is moved by two hydraulic actuators and suspended with a central spring. This spring cylinder is placed in the direct compression load path of a support rod connected with a rotational joint. If extended, this rod/spring arrangement is pushed through and rotates into coaxial alignment thereby taking up a major portion of the impact loads.

The retracted nose landing gear forms a compact arrangement.

The main landing gear leg is connected to the fuselage with a swivel axis. Attached to the swivel axis is a cantilever. Hydraulic actuators use the cantilever to create a rotational moment that actuate the main landing gear leg.

In contrast to the Arado 234, the E.395 was planned with a two man crew.

Original Sources

Another original drawing was found here: ( https://polska-org.pl/6831343,foto.html ). The drawing was apparently sold.

Data sheet from the German report, also to be found in the Lockheed report ATT 19152.

The model kit /scale 1/48 and 1/72) can be found here: LINK