The NG-3 'METEOR'; our first rival blaster

For this blaster we had to iterate ourselves through 17 different versions. Most deisgn solutions implemented on half- or full length darts where not applikable due to the different type of ammunition. Lets quickly dive into the main design drivers of this blaster.

Plenty of concepts have been investigated. Many of them were even manufactured, tested and improved upon.

Semi- or full auto

Rival ammunition has no directional preference if compared to foam darts, which have a preferred travel orientation. The rival ammunition can basically enter the fly wheels from any direction. So instead of having to align the magazine vertically, it can now be aligned horizontally with the main body of the blaster. If unlocked, the mag will now feed all balls into the fly wheels. Basically, you immediately end up with a full auto setup. One downside however, is the extensive rate of fire, which is basically uncontrolled. This proves to be problematic if your ammo capacity is limited. So with version v14 the design was revised to a semi auto action; Each trigger pull will launch a single ball. The main challenge here was to accomplish this without adding a complicated mechanism. So in the NG-3 the semi auto action is achieved without additional geared motors or solenoids.

Trigger pull and rate of fire

So with semi auto, you will be able to use your ammunition very economically. But, in order to still achieve a high rate of fire if necessary, the NG series uses a trigger return with linear force increase. This results in a very smooth and fast action. Initial designs had a single trigger which would also spin up the motors. The final design does however feature a separate rev trigger, which adds a little bit more control.

FPS

Currently, the NG-3 reaches a max 100fps with a 2s lipo setup. Ball type ammunition has a much shorter acceleration length compared to foam darts. So for the NG-3 the fly wheels had to be changed from the ground up. They are still 3D printed entirely in ABS.

Accessibility

The NG-3 feature a battery door at the rear of the main body. It does not require any tools to open it.

Additional features

Similar to the NG-2, the NG-3 will except 2s lipos measuring 58x30x15 mm. Both the 'Graphene 2s 950mAh 65c' from Outofdarts and the 'Turnigy Graphene Panther 1000mAh 2s 75c' from Hobbyking also fit.

The nozzle has a built in thread, allowing the installation of e.g. a hop-up or any other kind of barrel extensions (see image below for dimensions).

There is the possibility to also add a rear cover for those who prefer that option. But it is currently not part of the offer.

As usual you will find the NG-3 here in our online store

or on ETSY.

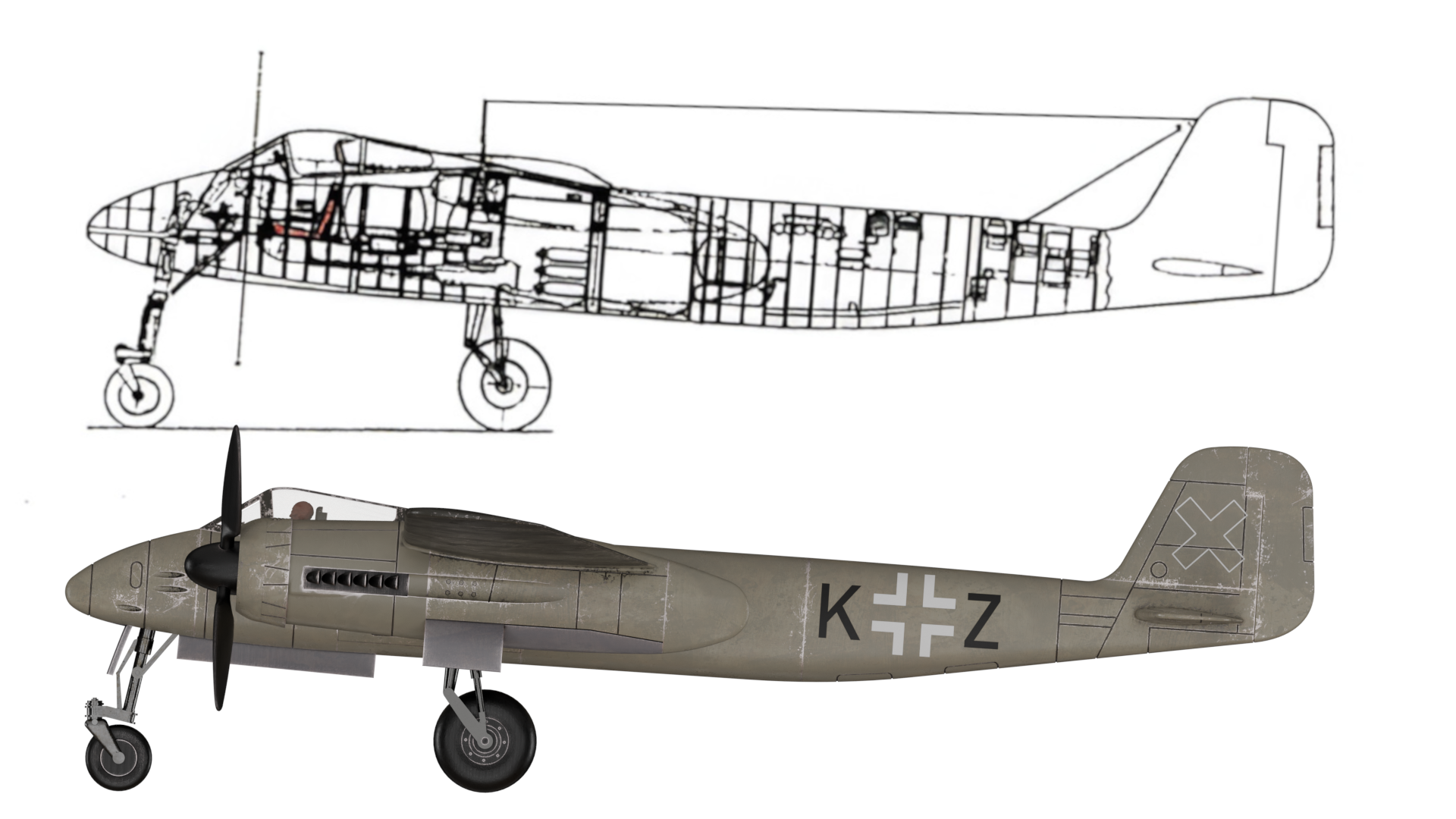

Bringing the Heinkel P.1068 to Life For aviation history enthusiasts and model builders, the Heinkel P.1068 is one of the lesser-known yet highly intriguing Luft ’46 aircraft concepts. Originally developed as a twin-engine competitor to the Arado Ar 234 , it evolved into a more advanced bomber featuring up to six engines. Though the He 343 project was ultimately canceled, the P.1068 survived in a different form—as a test aircraft built in collaboration with DFS (Deutsche Forschungsanstalt für Segelflug) . Now, you can bring this advanced jet bomber concept to life with our latest Heinkel P.1068-01 model kit , available exclusively at My3DBase .

Damit Eure Kekse mit unseren Backförmchen so richtig gut funktionieren haben wir für euch ein paar Tips zusammengestellt. Vorab einmal das Rezept: 100 g Butter 50 g Puderzucker (kann dem eigenen Geschmack angepasst werden) 30 g Ei 200 g Mehl Die Mengen können unter Einhaltung des Mischungsverhältnisses erhöht werden. Zunächst wird der Puderzucker mit der Butter vermengt. Danach wir das Ei hinzugegeben. Anschließend wird das Mehl untergehoben. Wichtig: Damit der Teig die richtige Konsistenz erhält sollte er gekühlt werden; ca 30min im Gefrierfach oder 1-2 Stunden im Kühlschrank.